COMSYS ADF Technology

PROVEN SOLUTION WORLDWIDE - ADF BENEFITS

-

1. SPACE

Since one module supports multiple drives, you can save space and ensure flexibility for the future. You can use many ADF Filters together, since it is Modular. Compensate current from 30A to in excess of 10,000A.

-

2. MONEY

Increase energy efficiency while reducing the expense of replacing worn equipment.

-

3. TIME

Avoid unnecessary downtime for maintenance or replacement of equipment affected by power quality issues.

-

4. HASSLE

ADF-type technology is already being included in regulatory demands and equipment warranties — a trend that will only continue to grow.

VIDEO: ADF Low Harmonic Solution | Overview

Technology that makes energy more efficient

Reduce Energy Losses and Meet Compliance

COMSYS ADF enables you to meet power quality regulations and reduce energy losses through harmonic compensation, load balancing, flicker compensation, and resonance elimination. The ONLY All-in-One Solution.

These disturbances include network unbalance, flicker,

and especially harmonics — not to mention the risk of

regulatory non-compliance. Those working in the marine, offshore, and water treatment industries are especially vulnerable to these problems.

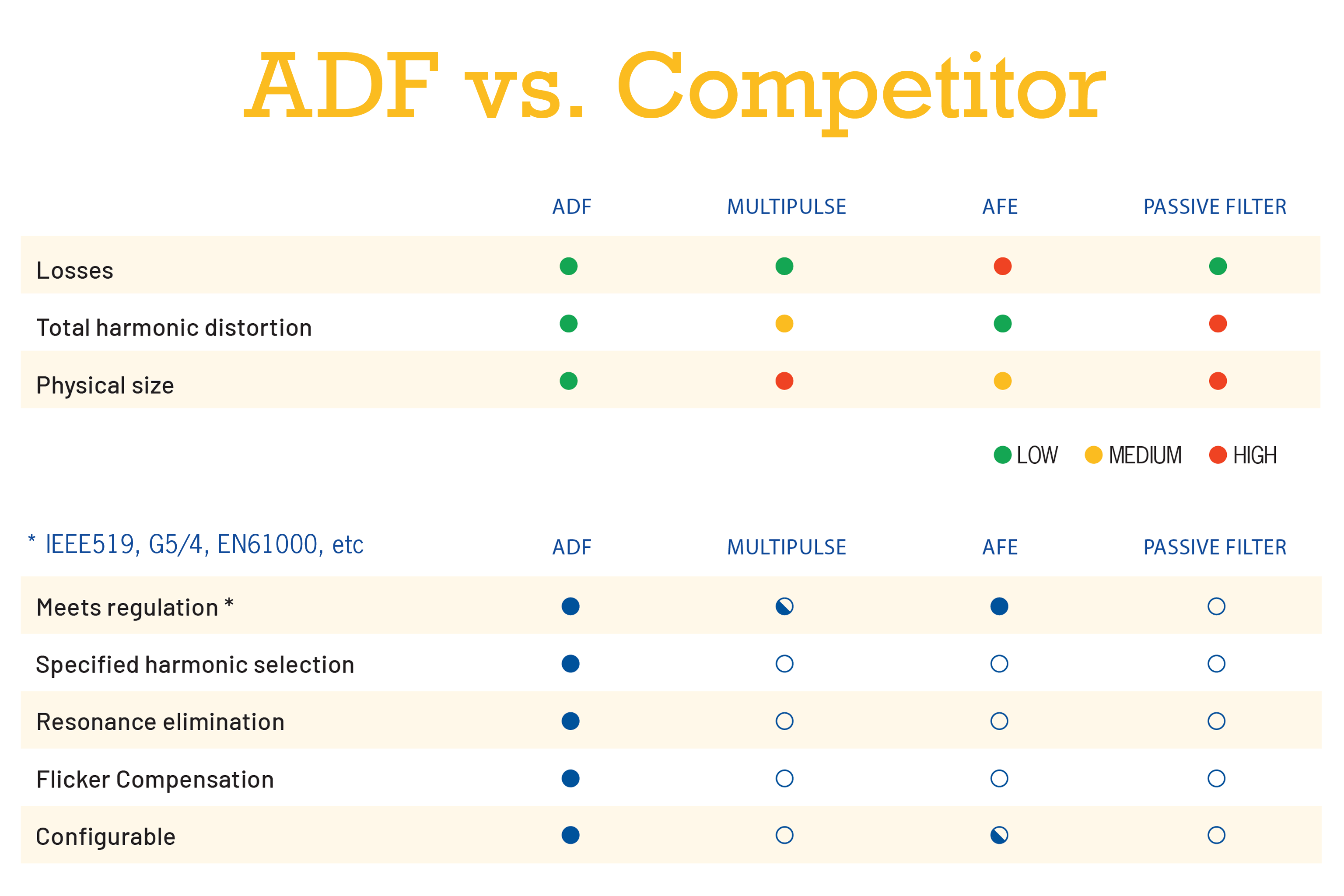

Modern solution that offers an improved competitive advantage compared to traditional passive filters. With active harmonic filter technology, you get a more compact solution that enables fewer losses and less total harmonic distortion (THD).

What to expect with ADF?

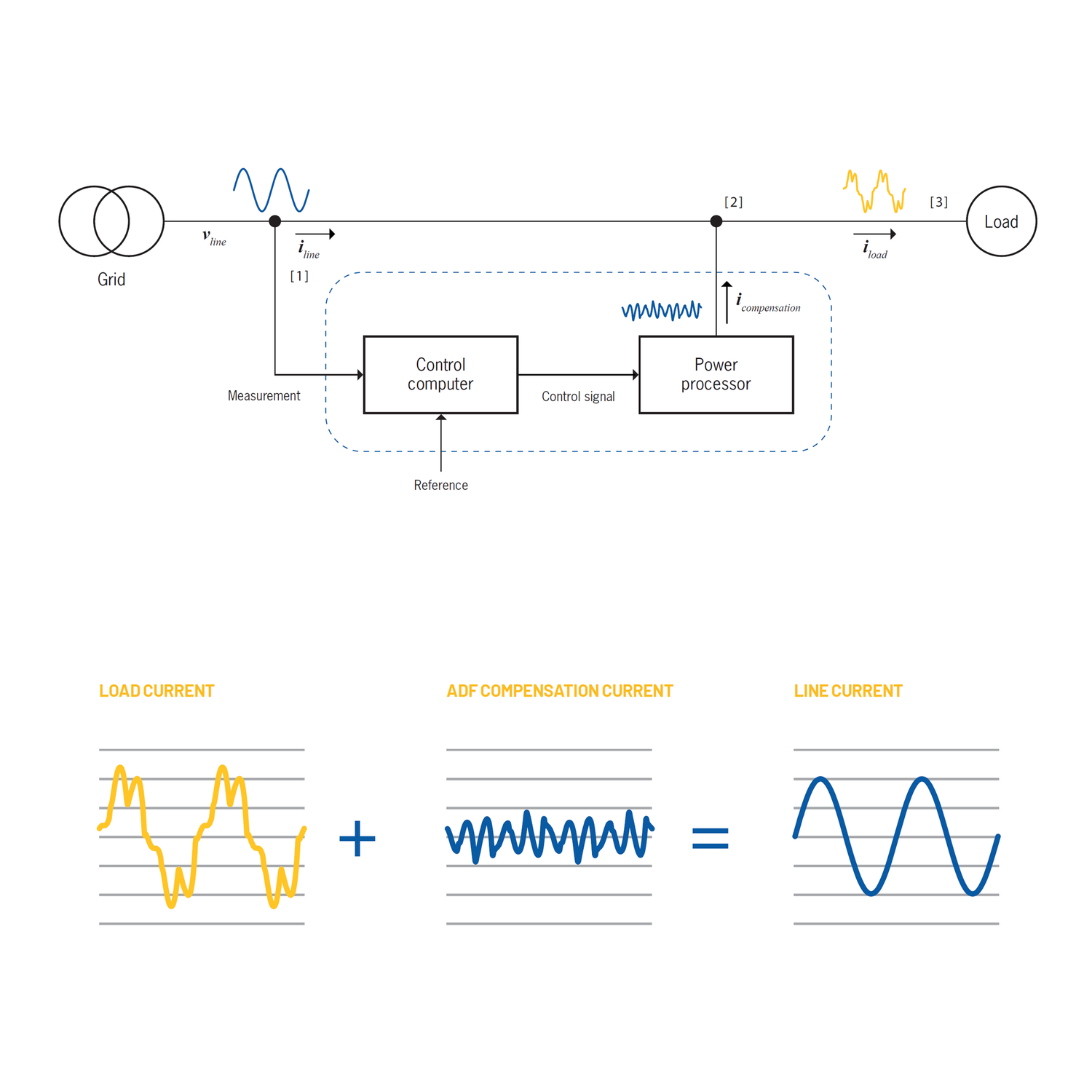

ADF Operating Principle - How it Works.

An ADF unit is basically a very advanced computer-controlled current generator with the ability to instantly produce any shape or form of compensation current.

A simplified diagram of the operating principle is shown in the figure. Each ADF unit is connected in parallel, in shunt, with the load that requires compensation.

- The power flows of electrical currents between the load and the network are measured and analyzed [1] to determine if disturbances such as reactive displacement and /or harmonics are present.

- If found, the ADF unit injects compensation current [2] that are the exact opposite of, for example, the harmonics and/or reactive displacement.

- This is done in order to cancel out the load behavior [3].

NO CTs Required. The ONLY solution with Sensorless Control

When you need a retrofit solution or you have a complicated set-up, it can be very difficult to add the CTs (current transformers). But with Sensorless Control, we can compensate without it — so you can eliminate the CTs altogether. This gives you more flexibility when it comes to where and how to install the ADF unit and reduces the overall hassle of installation and compensation. In addition to this, you are also able to isolate sub-grids and compensate background distortion, which further improves the flexibility and adaptability of the ADF platform.

Sensorless Control is now available on all ADF products.

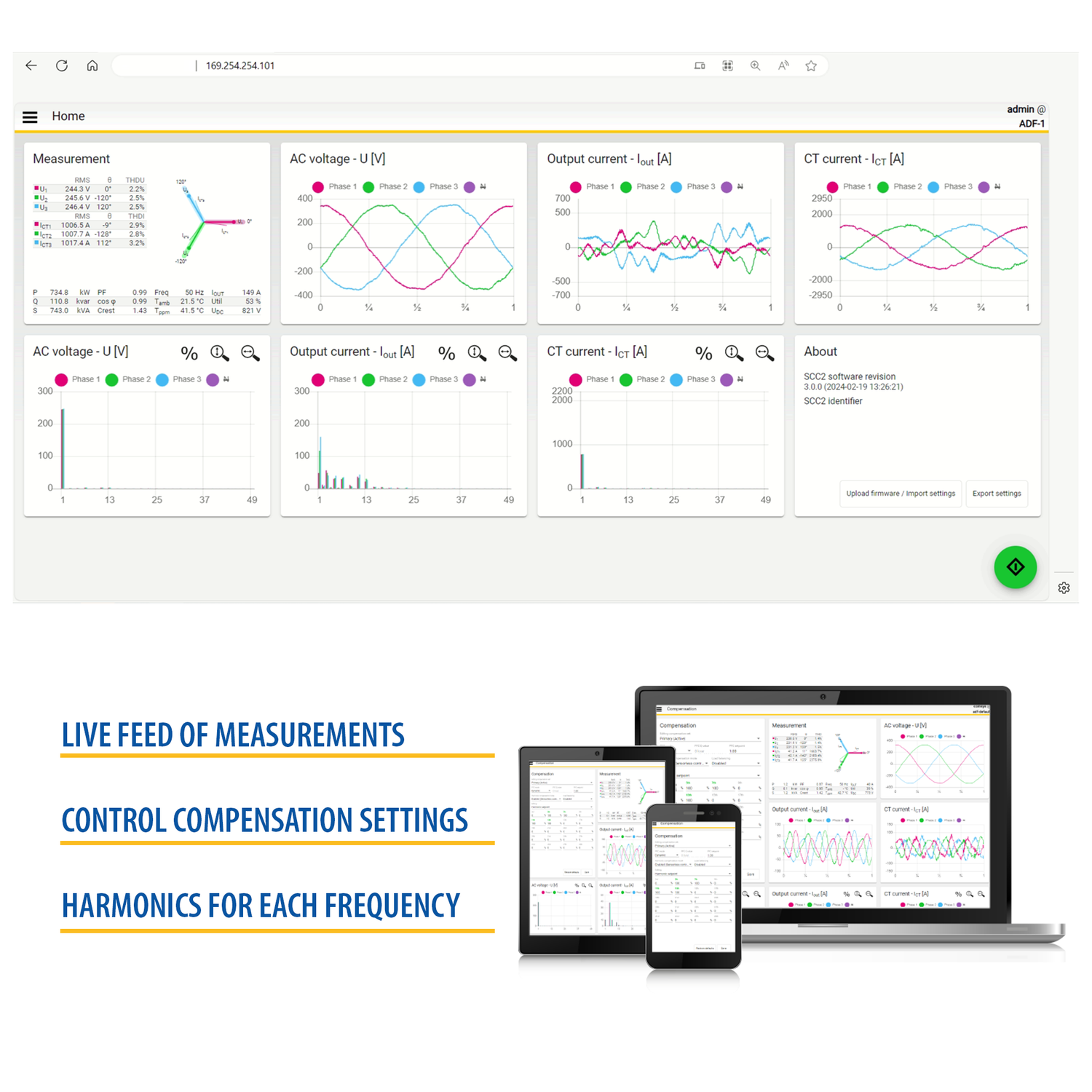

Remote Monitoring and Control of ADFs

The WUI (web user interface) is a web application requiring no additional software installation. It offers a convenient, easy-to-use service to enable you to monitor your ADF modules from any device – anywhere, anytime. Additionally, the WUI can be integrated into a larger system (i.e. with multiple generators, many loads, etc.), which you can then choose to run on a certain schedule or operation mode. And if your operation uses a PLC, the PLC can read out critical data from the ADF module automatically.

Explore COMSYS ADF Series

-

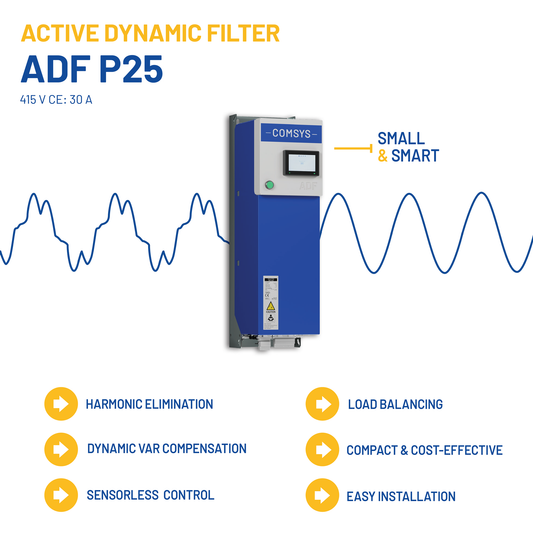

COMSYS ADF P25 Active Harmonic Filter

Regular price $0.00 AUDRegular priceUnit price / per -

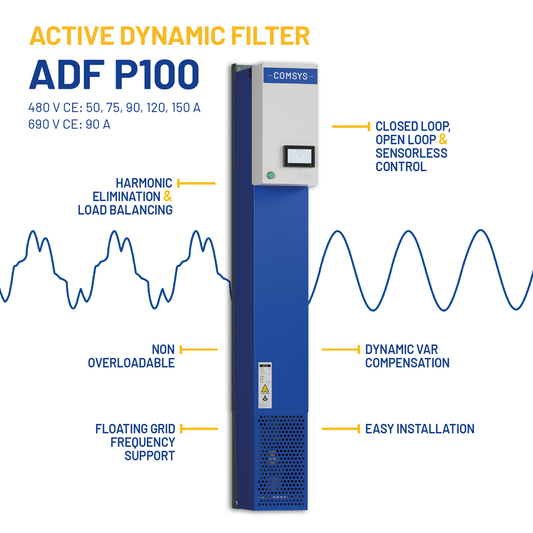

COMSYS ADF P100 Active Harmonic Filter

Regular price $0.00 AUDRegular priceUnit price / per -

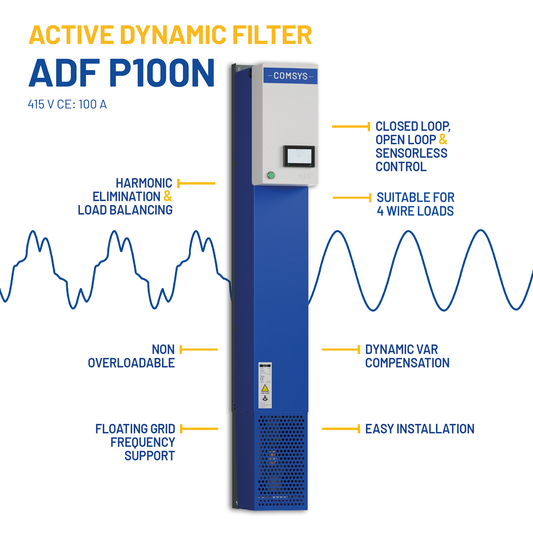

COMSYS ADF P100N Active Harmonic Filter

Regular price $0.00 AUDRegular priceUnit price / per -

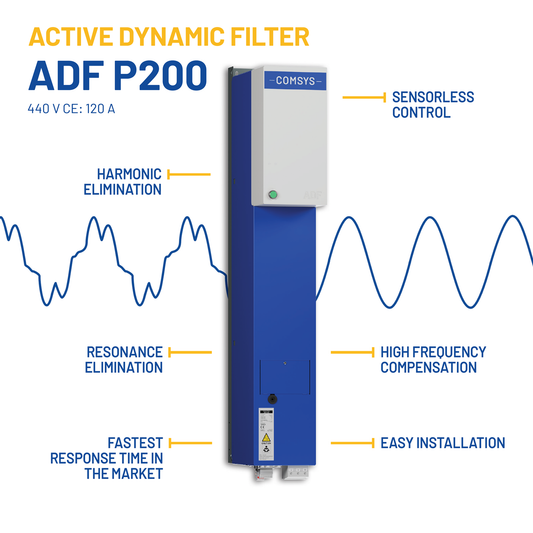

COMSYS ADF P200 Active Harmonic Filter

Regular price $0.00 AUDRegular priceUnit price / per

Case Studies & Our Projects

ADF have been integrated into diverse applications around the world. From data centers in Korea to a Live Fish Carrier in Norway, see how ADF enhances customers operations.

Supreme Technology & Energy Solutions Australia Receives Prestigious COMSYS Largest Project Award for Cross River Rail Project in Brisbane

Presented at the COMSYS ADF Conference in 2020, Supreme Technology & Energy Solutions Australia Pty Ltd, an affiliate company to SmartGRID Technologies, wins the Largest Project Award in the World, for the Cross River Rail Project with 19 x COMSYS ADF P300 Active Harmonic Filters.

The construction of the tunnels commenced in 2021 and requires digging and boring directly under the city centre. Large tunnel boring machines, tunnel fans and pumps are the largest loads during the construction phase and all of these loads are controlled by Variable Speed Drives. The Cross River Rail will be passing very close to some of the most sensitive buildings in the CBD, including several hospitals and The Brisbane / Gabba Cricket Ground. For this reason, there has been a strong focus on power quality already from the start of this project, with very strict limits on harmonic levels.

COMSYS ADF Active Harmonic Filters Commissioned for Sydney Metro Tunnelling Project

We have recently commissioned 8 x P300 COMSYS Active Dynamic Filters (ADF) for the Sydney Metro Project.

These harmonic filters will compensate for the tunnel boring machines (TBMs), tunnel fans, pumps, and other loads controlled by variable speed drives (VSDs).